RELATED Bottling & Capping PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers a wide range of bottling and capping solutions that handle containers going into and coming out of filling operations. With automated solutions to unscramble and orient bottles, apply caps and closures, and create multipacked products, ProMach helps customers create the most productive primary packaging operations with more than 18,000 systems shipped around the globe.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

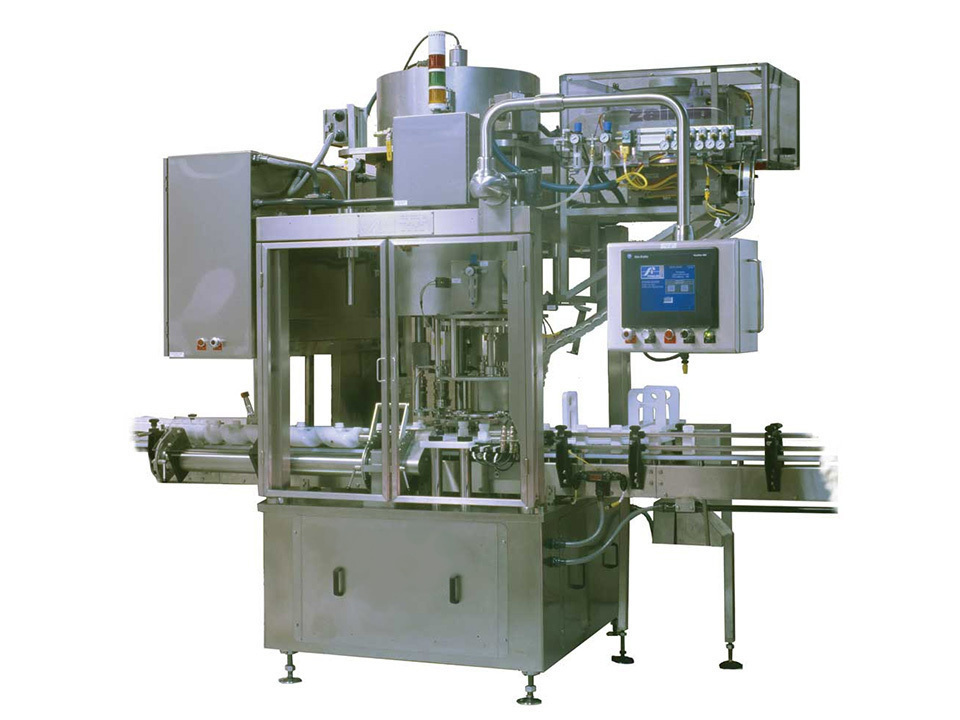

learn moreA typical Insert + Close system would include the following components downstream of the filler:

- Cap elevator(s),

- Cap orienter(s), and

- Capping turret station(s)

Depending on the application, one or more of each these system components may be required. Regardless of the required quantity, each and every system component will be specifically designed and configured to meet or exceed customer requirements.

Zalkin Insert + Close system highlights:

- Speeds up to 300 cpm (18,000 cph)

- Capable of running a wide range of pump and spray fitments, closure types and container sizes

- Dip tube lengths up to 280 mm

- Dip tube elevators, cap elevators, dip tube orienters, cap orienters, and capping heads are application specific versions of proven Zalkin technology

- Components are designed to fit the requirements of each application – custom designs are offered

- Stainless steel construction