RELATED Bottling & Capping PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers a wide range of bottling and capping solutions that handle containers going into and coming out of filling operations. With automated solutions to unscramble and orient bottles, apply caps and closures, and create multipacked products, ProMach helps customers create the most productive primary packaging operations with more than 18,000 systems shipped around the globe.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreMore Info About Servo Capping Heads

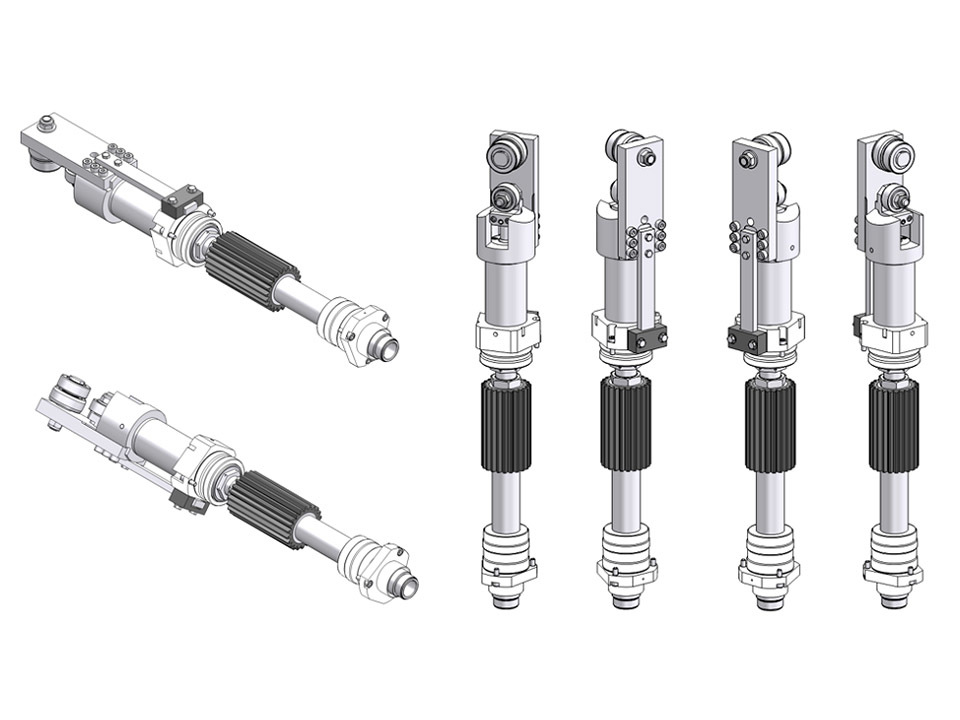

- Electronic Servo MotorsServo capping heads replace magnetic torque control systems with the precision performance of electronically controlled servo drives and motors. Each servo capping head includes its own servo motor and drive which provides precise, consistent cap application from every capping station.

- HMI Torque AdjustmentsApplication torque is set via the HMI and torque adjustments via the HMI are fast and precise.

- No Mechanical ComponentsServo capping heads eliminate mechanical components such as gears and rotating spindles. Capping chucks also mount directly to the servo motor which eliminates any loss of application torque versus belt drive systems.