ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more!! BRAND NEW !! H6 Compact Screw-on Capping heads

- H6 TECHNOLOGY FEATURESReliable & accurate ; Easy to use

- ADDITIONAL BENEFITS WITH THE H6 COMPACTOptimized Installed Base ; Efficient Maintenance Procedure ; Overall Cost Time Savings

H-Series

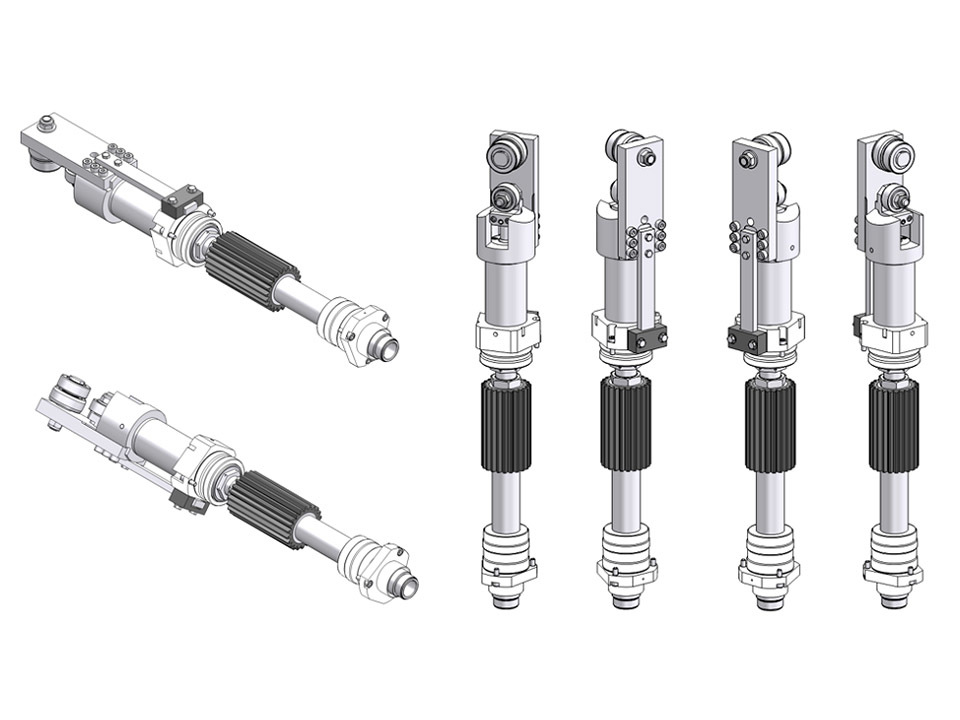

The H-Series of constant magnetic torque screw-on capping heads, also referred to as hysteresis heads, includes three models:

- H5 – Ideal for a wide range of cap types, sizes and industries for speeds up to 600 cpm and torque requirements below 50 inch-pounds. H5 heads accommodate both segmented jaw and solid ring capping chucks.

- H2 – Ideal for high torque applications over 50 inch-pounds.

- H6 – Zalkin’s newest constant magnetic torque capping head is a low-inertia alternative to M5 oscillating magnetic torque heads. H6 heads combine the high-speed capabilities of M5 heads with the smooth performance of constant torque technology. It is ideal for high operating speed production environments including carbonated soft drinks, bottled water and other beverage applications.

M-Series

M-Series screw-on capping heads feature oscillating magnetic torque application and control. They are ideal for:

- High speeds, up to 1,350 cpm (81,000 cph)

- Small closures from 28 - 43 mm

- Torque requirements from 1 - 36 inch-pounds

- Bottled water and carbonated soft drink applications

They are rugged, durable and inexpensive. Their waterproof design is well suited to demanding high-speed beverage production environments.

M-Series capping heads are offered with two chuck styles:

- Segmented jaws, which open and close

- Solid rings, molded for each cap (plastic or steel)

As with all Zalkin capping systems, M-Series chucks offer quick connect convenience for fast closure and chuck changeovers.

Servo

Servo driven screw-on capping heads use servo motion control to replace magnetic torque application and control clutches. Each capping head is powered by its own dedicated servo motor.

Servo capping heads are ideal for:

- Low, medium and high speeds, up to 1,350 cpm (81,000 cph)

- Torque range 7 to 88 inch-pounds

- Wet production environments including beverage and food

- Precise chuck control & cap orientation

- Monitoring and recording capping head performance for every applied closure - applied torque is measured and captured for every cap applied to every container

Screw-On Capping Head Components

- Chucks – the capping head component that comes in contact with the cap, grips it, rotates it, and applies it. Multiple chuck designs are available to accommodate a wide range of screw cap types and geometries.

- Head slides – the spindle assembly that connects the capping head to the cam. Head slides control the vertical and rotary motion of the capping head.

- Torque setting & torque adjustment dial – torque settings are precisely set and adjusted via an easy to use tool-less, adjustment dial.

- Top load setting & adjustment dial – top load pressure is precisely set and adjusted via an easy to use, tool-less adjustment dial.