RELATED Bottling & Capping PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers a wide range of bottling and capping solutions that handle containers going into and coming out of filling operations. With automated solutions to unscramble and orient bottles, apply caps and closures, and create multipacked products, ProMach helps customers create the most productive primary packaging operations with more than 18,000 systems shipped around the globe.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

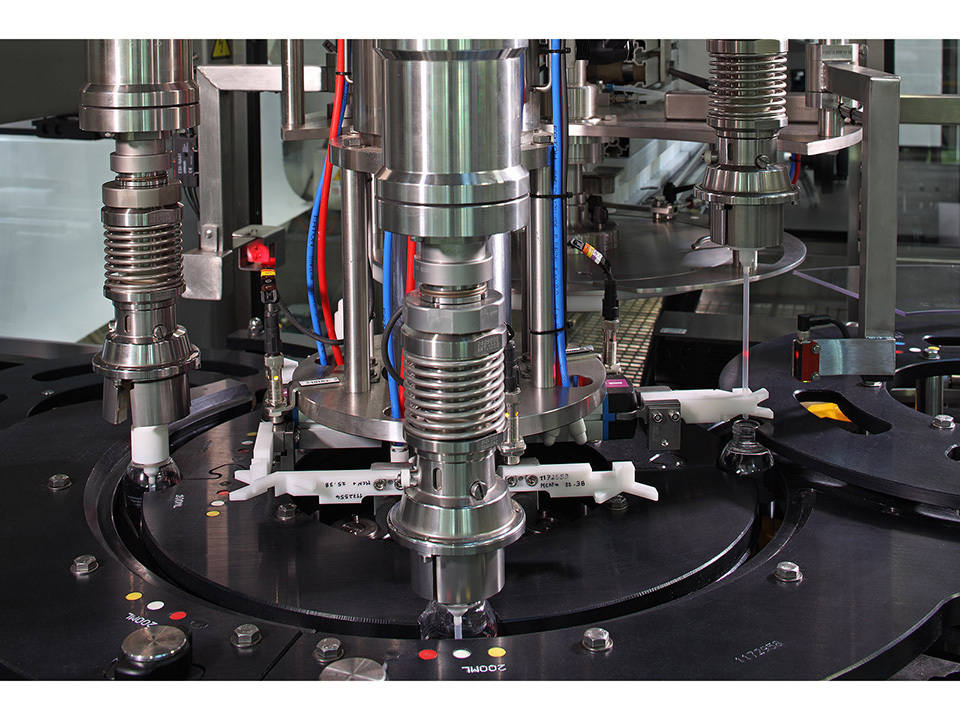

learn moreZalkin Repair Kits used as part of a proactive maintenance programs:

- Improve operating efficiency

- Reduce bad or misapplied cap application

- Increase the useful life of your heads, head slides, and chucks

- Help support regularly and timely execution of maintenance programs by having required parts on-hand and ready to install

Additional Information:

- Zalkin recommends rebuilding capping heads and chucks at every 6,000 hours and headslides at every 18,000 hours.

- Zalkin recommends annual audits to ensure that your plant conditions do not warrant more frequent routine maintenance.

- Check the Maintenance Plan in your manual to ensure timely maintenance on these vital assemblies.