RELATED Bottling & Capping PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers a wide range of bottling and capping solutions that handle containers going into and coming out of filling operations. With automated solutions to unscramble and orient bottles, apply caps and closures, and create multipacked products, ProMach helps customers create the most productive primary packaging operations with more than 18,000 systems shipped around the globe.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

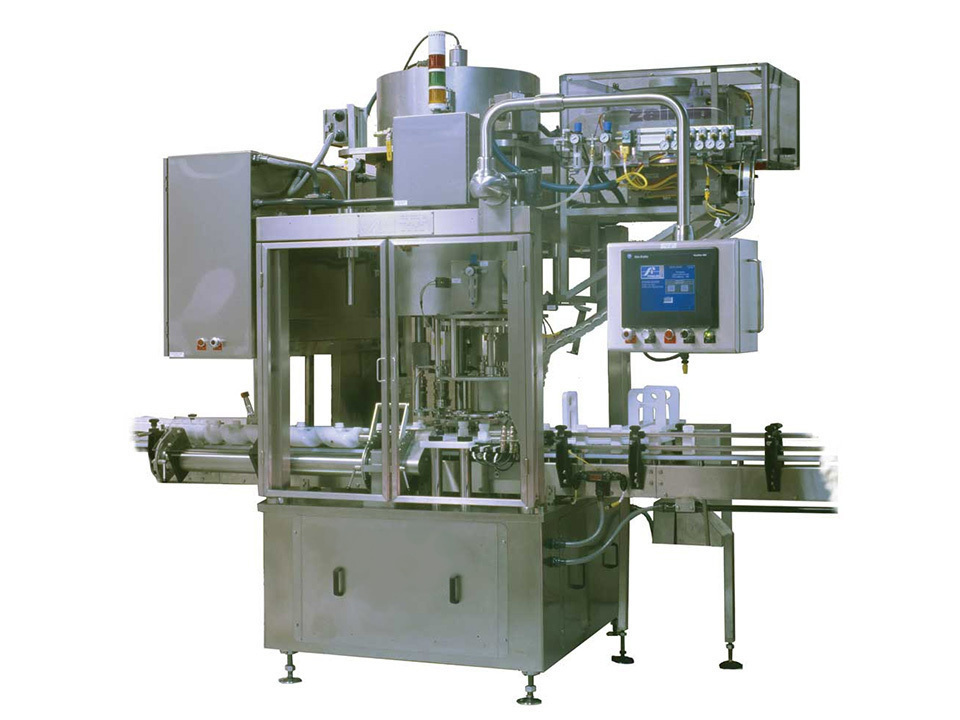

learn moreFreestanding rotary roll-on capper highlights:

- Multiple models and options accommodate a wide range of speeds and applications

- 3 to 24 capping heads

- Five standard pitch diameters: 300, 360, 480, 640 & 720 mm PCD

- Stainless steel construction

- Closure diameters from 18 mm to 38 mm

- Three different diameters of roll-on sealing heads

- Suitable for short skirt or long skirt

- Fast capping head changeover

- Custom pitch diameter configurations are available

- Multi-turret configurations on the same base are available

Key Zalkin roll-on capping head components and their functions:

- Pressure Block – Captures the closure, centers it over the bottle’s neck finish, compresses the top of the cap and cap liner, and tightly forms the cap around the outer rim of the container’s neck finish. The pressure block is responsible for creating the seal of the closure to the container.

- Top Load Springs – Four top load springs provide the sealing force for the top of the closure and compensate for variations in container heights. This is particularly important for glass bottles.

- Side Load Spring – Applies pressure to the to the closure skirts during the application process to assure the entire closure conforms to the container.

- Thread Roller – Forms threads directly to the skirt of the aluminum cap and into the neck finish threads on the container. The thread roller precisely follows or traces the bottle finish threads to assure the closure will be easy to open and reclose. It essentially marries the aluminum closure to the container’s neck finish.

- Pilfer Roller – Forms the tamper evident feature at the lower end of the aluminum closure skirts.

Popular roll-on sealing head options include:

- Quick release fittings – tool-less head changeover in less than 20-seconds per head

- Stainless Steel – Easy to clean and maintain upgrade versus standard brass heads.

- Ultraclean Stainless Steel – Ideal for beverage and food applications